DEIF has a strong track record in developing emergency, standby and backup power solutions for mission-critical facilities and businesses including life safety, medical, industrial process control, data centres, telecommunications, and television and radio broadcast systems.

Resilient turnkey packages, DEIF’s solutions incorporate intelligent power distribution and controls, switchgear, and generator and grid protection to guarantee uninterrupted power supplies in cases of mains failure.

We design and integrate Power Management Systems with unique standby capacities and can deliver record start-up from an impressive six seconds for multiple gensets in parallel, redundant control systems, or even an entire redundant power plant.

Find out more about products and case studies at:

- https://www.deif.com/subsegments/critical-power

- https://www.deif.com/land-power/cases

- https://www.deif.com/land-power/applications/automatic

Application Examples

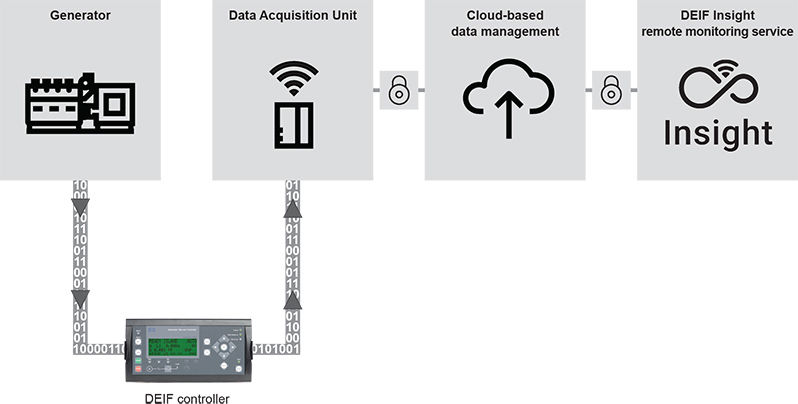

APPLICATION: Remote monitoring

Customisable dashboards

With a wide range of data visualisation options, you’ll be able to customise the DEIF Insight dashboards to your needs and afterwards monitor your equipment remotely.

Easy setup

Simply connect your equipment, then set up the communication parameters (tags) and notifications in three simple steps. If necessary, you can even control who has access and customise permissions based on your requirement.

Cloud data management

The cloud runs event-based logging, meaning it only stores data when changes occur. The data is stored securely in the cloud.

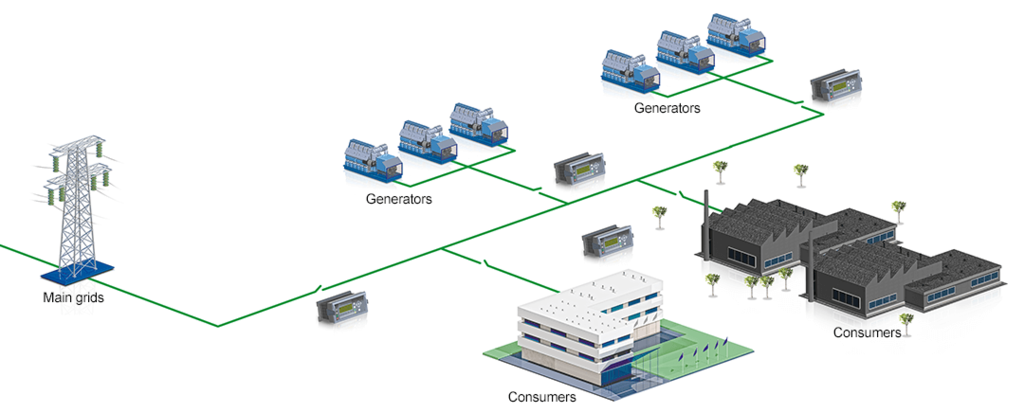

APPLICATION: Automatic load control

The ALC Automatic Load Controller is an integrated part of DEIF power management systems. In case of generator drive when the mains grid is not available, it may be necessary to control the system load. When the ALC is placed in a section of the system, it will be capable of controlling up to 8 consumer feeder breakers.

One system can hold up to 8 ALC units, giving the possibility to control up to 64 feeder breakers. For each feeder breaker, the control can be based on a fixed power consumption value for the consumers connected to the feeder, or it can be based on a power measurement feeding a 4-20 mA signal into the ALC unit.

Based on the power calculation in the system, the ALC’s can automatically connect and disconnect consumers in a pre-determined order. This means that if a generator is tripped for any reason, the system will calculate the power flow and disconnect the necessary number of consumer feeders in order to prevent overloading the plant. If a generator has been taken out and is made available again, the system will calculate if the generator is necessary to feed the system. If so, the generator is started and, when online, the consumer feeders will connect.

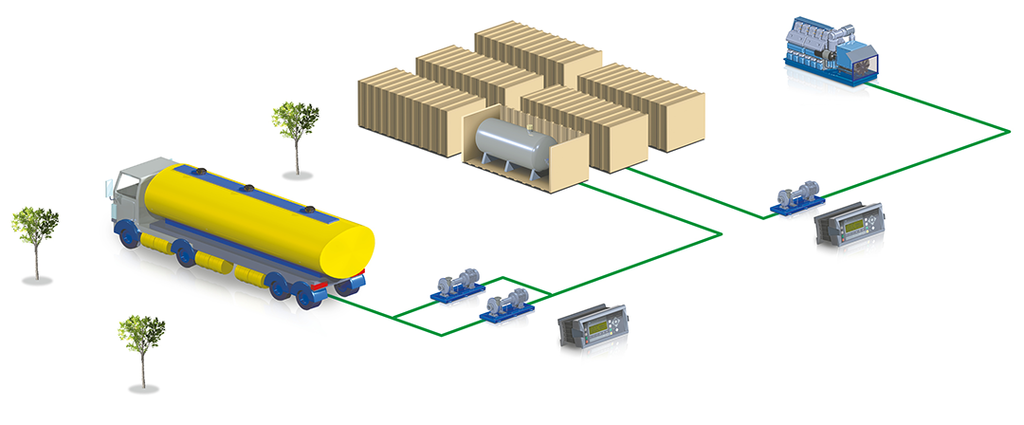

APPLICATION: Automated Fuel distribution

The Automatic Fuel Controller, Plant Management (AFC PM) is a series of controllers designed to control fuel logistics in liquid fuel fired power plants.

AFC PM uses multiple, smaller, decentralised fuel tanks rather than large centralised fuel tanks. Fuel is transferred to the fuel tanks from designated pump station(s).

Manually controlled valves inserted on the fuel pipe can be used to separate pump station and fuel tanks.

The solution’s maximum capability is 32 pump stations or fuel tanks; an application with one pump station can have a maximum of 31 fuel tanks, supporting a maximum of eight separation valves. More systems can be added to operate individually.

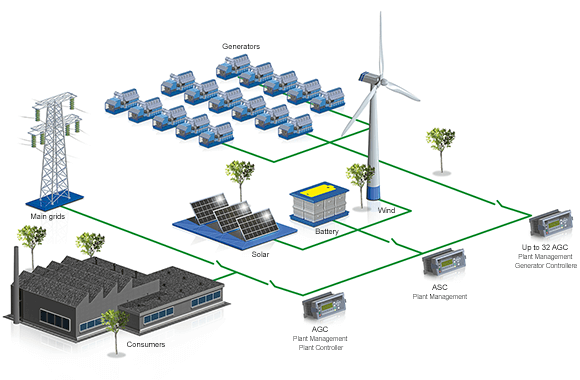

HYBRID APPLICATION: Automatic island mode

The ASC PM interfaces with the inverters of the non-conventional generator supply to create systems that allow conventional generators to run in parallel with non-conventional supply: PV (solar), a battery or a wind turbine system for instance.

The non-conventional supply (NCS) is handled as a base loading power and reactive power provider, not as a voltage and frequency provider. This means, the ASC PM only operates the NCS when either utility or a genset constitutes a grid ready to receive power.

The maximum capability of stand-alone applications is 16 gensets, one mains and one NCS plant.

The ASC PM is fully integrated in the DEIF Application Configuration and SuperVision PC tool for DEIF Power Management Solutions. The DEIF power management system fully integrates the NCS plant and the conventional genset plant. The ASC PM can control pure off-grid, pure grid-tied, or a combination of the two.